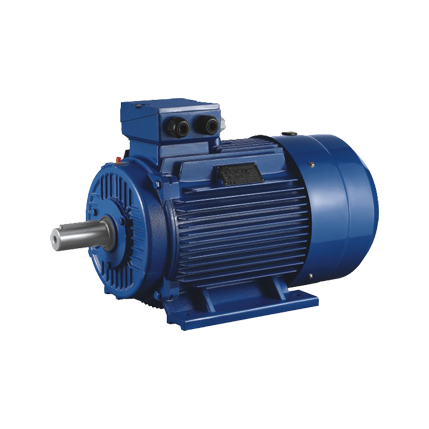

Summary:YE3 three-phase motors are a very popular motor type used in a variety of applications including pumps, compressors, electric motors and fan motors. These motors are designed to be very energy efficient, using up to 15% less electricity than standard......

YE3 three-phase motors are a very popular motor type used in a variety of applications including pumps, compressors, electric motors and fan motors. These motors are designed to be very energy efficient, using up to 15% less electricity than standard motors. They feature a new winding design and low-loss silicon steel sheets, meeting the secondary efficiency standards of IEC60034-30-2008.

High-efficiency motor saves 15% electricity than ordinary motor

Rare earth permanent magnet high-efficiency energy-saving motor is an excellent substitute for asynchronous motors. This type of motor saves up to 15 c/o of electricity.

Energy-efficient motors reduce operating costs and extend the life of the system. Depending on the manufacturer, energy-efficient motors can cost less than standard motors.

There are various ways to evaluate the efficiency of a motor. You can start with a motor efficiency graph. It shows the speed of the motor, the size of the motor, and the power consumed by the motor.

When it comes to motor efficiency, it is important to consider both the actual energy cost saved and the total energy cost. Actual electricity savings will depend on motor size, electricity rate, size and load.

Generally, the greatest savings are found in variable torque loads. These types of loads require the motor to produce more torque as speed increases. They are usually associated with centrifugal fans. However, there are many other applications for these types of motors.

One of the main advantages of a motor designed to achieve a specific level of efficiency is that it can provide soft starting and soft stopping. Typically, both of these benefits can be achieved by using a frequency converter to regulate the speed of the motor.

Another advantage of energy-efficient motors is reduced rotor resistance. Most manufacturers design their motors for peak efficiency at 75% to 100% of load.

Energy-efficient motors also have higher inrush current, which is the first current that flows when the motor starts up. This initial inrush current can be as high as 13 times the full load current of a standard motor. However, it only lasts for a fraction of a second, and it's too short to trigger the thermal protection.

The main purpose of this standard is to establish efficiency classes for direct-on-line motors. This is also an effective way to differentiate manufacturers and suppliers by using appropriate indicators. Using this tool to your advantage can create a win-win situation for both the manufacturer and the customer. One of the many benefits of the standard is that each product is rated and measured against the appropriate specifications. Additionally, the resulting documentation is easily consumed and verified by buyers. Finally, it facilitates the issuance of certificates in the form of official IEC accreditation certificates.

Another notable feat is that the IEC's IEC 60034-30-2008 standard is the only standardized efficiency test validated by an industry leader. Therefore, it is an ideal test method for certifying the latest green technologies. Considering the increasing demand for electricity, it is imperative that we take a proactive stance on this topic. For this reason, this standard is a must-have on your company's wish list. Fortunately, you can easily download a free copy of this document, along with a host of other energy efficiency standards from various vendors. Based on these criteria, you will be able to evaluate the best products and services for your organization. By doing this, you can ensure that the right people get the most lucrative contracts. With such a veritable treasure trove of knowledge, you are guaranteed to be in the best position to land your next big contract. To do this, you should take the time to peruse the latest IEC testing standards and you should be able to acquire the elements needed for a successful power transmission business. Getting certified is a great way to build your brand and increase your profits in the process.

New winding design and low loss silicon steel sheet

The invention relates to a three-phase asynchronous ultra-high-efficiency electromagnetic design. Especially the new low-harmonic winding design with single-layer and two-layer hybrid.

In general, both winding copper losses and motor losses are affected by temperature. However, the influence of temperature on stator iron loss is relatively limited. Therefore, a new design of single-layer and double-layer low-harmonic winding can effectively reduce the loss and improve the performance of the motor.

First, the winding copper loss varies nonlinearly with decreasing temperature. This results in higher iron losses in the motor stator. Under DC power supply, the difference in stator iron loss in different modes is greater than 30%. With a PWM supply, the difference is within 20%.

Second, the copper shield can reduce the eddy current density in the permanent magnet. This can greatly reduce rotor eddy current losses. It has a strong inhibitory effect at low temperature. Also, the thickness of the copper shield can be changed without changing the thickness of the permanent magnet.

Third, the new low-harmonic winding design can reduce eddy currents in the rotor and improve the shielding effect of other parts of the rotor. As a result, the supply current decreases. At the same time, the motor efficiency is improved.

4. YE3 series ultra-efficient motors have high magnetic permeability and low noise. Applicable to all kinds of mechanical equipment. Meet the EFF1 index and GB18613-2006 energy-saving evaluation value requirements. In addition, the rated output can withstand 1.5 times the rated current for 2 minutes.

Fifth, the new VPI vacuum immersion plating process can significantly enhance the ability to withstand voltage shocks. It also reduces the turn-to-turn and phase-to-phase insulation accident rates. Finally, the new winding design and low-loss silicon steel sheets can achieve the purpose of the present invention.

Low temperature experiments were carried out on 50W310 silicon steel sheet. Material properties were compared at room temperature and at 20 °C.

application

Three-phase induction motors are widely used in many industrial applications. They offer excellent efficiency and are extremely strong. Some of the most common applications include pumps, compressors, winding machines, turbines and appliances.

Three-phase induction motors are based on the principles of Faraday's law of induction. Induction motors have low vibration, high starting torque, and good PF ratings.

A three-phase induction motor has two main parts: a stator and a rotor. The rotor is a circular structure containing an induction coil. These coils are wrapped with wire. When the rotor rotates, a current is generated, which is called the rotor circuit. A fan is mounted on the rotor to cool the motor.

YE3 (IE3) three-phase motors are suitable for various general mechanical equipment. They have class 2 energy efficiency and good performance. They are safe and easy to maintain. YE3 (IE3) motors are made of high-quality materials.

YE3 (IE3) motors have high starting torque and are cooled by enclosed fans. They can meet the efficiency requirements of IEC60034-30. They are also suitable for various applications. You can use them in the following fields: conveyors, lifting industry, cranes and oil pumps.

YE3 (IE3) motors can reach the same efficiency level as American NEMA super-efficient motors. This makes them highly competitive. Compared with standard single-phase and three-phase asynchronous motors, YE3 motors are optimized in terms of design, structure, and materials. In addition, it has an ISO 9000 certificate.

In addition, YE3 (IE3) motors have excellent electromagnetic properties. Due to its large starting torque, it can drive various types of mechanical equipment. Can be used in the petroleum industry, chemical equipment, and even blowers.

Another advantage of YE3 motors is low copper consumption. Compared with standard single and three-phase asynchronous motors, the price of YE3 motors is reduced by 366 yuan. Therefore, it is a more cost-effective product.

The voltage tolerance of YE3(IE3) motors is +-5%. But they cannot be used in corrosive workplaces. If you want to choose a YE3 (IE3) motor, you should carefully consider the following points.

Product Features

YE3 series ultra-high-efficiency motors are fullyenclosed three-phase asynchronous motors

manufactured with new materials and new processes.

lt has beautiful appearance, high efficiency andenergysaving, F-class insulation, IP55 protection level,low motor noise, small vibration, and reliable operation.lt is a generaluse place that requires energy-savingcontinuous operation and can work frequently.Suchas fans, pumps,etc.

![]() NO.1828 Haichang Road, Binhai Industrial Park,

Jiaojiang District, Taizhou City, Zhejiang

Province,China

NO.1828 Haichang Road, Binhai Industrial Park,

Jiaojiang District, Taizhou City, Zhejiang

Province,China

![]() Export department:

Export department: ![]() General manager:+86-13606763355

General manager:+86-13606763355

English

English 中文简体

中文简体 Deutsch

Deutsch عربى

عربى Español

Español